13. Domestic Uses of Ceramics

| 1832 Page: 358 of 418 Go To Page: | ◁◁ First | ◁ Previous | Next ▷ | Last ▷▷ |

Ceramics that can withstand direct fire are indispensable for the lining of domestic open fires, in wood burning stoves, and for flues and chimney pots. They are made from refractory (heat resistant), low plastic clay.

Victorian decorative washbasin and Doulton

saltglaze stoneware toilet, 1890 - Image

courtesy of the Potteries Museum and Art

Gallery, Stoke-on-Trent

The bodies of early sanitary ware were earthenware, but now they are vitreous, some stoneware but mostly porcelain. Most are made by slip or solid casting, with great care taken in drying and firing to avoid cracking because of their large size.

Victorian bedroom and bathroom wares were very decorative, as were fireplaces. Colourful washbowls and water jugs were popular when running water was not available.

Today most wall tiles are made with a glazed porous body, although early versions crazed due to water ingress. Floor tiles generally have a vitreous body and are usually pressed to shape, have metal oxide body colour and are unglazed. Some tiles are conductive to dissipate static electricity.

13.3 Kitchen and Tablewares

Domestic kitchen and tableware can be made from non-vitreous earthenware, semi-vitreous ceramics, vitreous porcelain or bone china.

Early ceramics for food preparation included fish scalers, having rough bases, and a variety of ceramic equipment for grinding food including Roman mortaria.

Two grinders, Indian and Chinese Tang -

courtesy Chennai Museum and source Hong

Kong Museum; Egyptian fish scaling dish,

Middle Kingdom, UC18812 Copyright of the

Petrie Museum of Egyptian Archaeology, UCL;

and Roman mortarium, 2-3rd centuries BC,

courtesy Collector-Antiquities

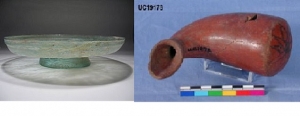

Roman green glass plate 300 AD, and

Egyptian Dynasty 18 salt horn, UC19178

Latter Copyright of the Petrie Museum of

Egyptian Archaeology, UCL

Vessels were made of ceramics or glass, the latter becoming more common from Roman times.

The problem of using ceramics for cooking is that if a vessel is heated rapidly the stresses can be uneven setting up areas of tension or compression, and if the tensile strength is exceeded, the vessel will crack. This was an early problem for man, as cooking was the earliest application of ceramic vessels. However, as mentioned earlier, a porous body is more accommodating as cracks naturally terminate on pores, so earthenware is more tolerant to heat, even though its coefficient of expansion is high, relatively similar to bone china. Unfortunately, although bone china is one of the strongest bodies mechanically, its high expansion coefficient makes it unsuitable for cooking, although it can be taken from the fridge to boiling water but not direct heat above 100 ºC. However, much delicate and decorative tableware has been made from bone china.

Most pottery can be made fully ovenproof, even earthenware, by replacing the silica with alumina. However making it completely “flameproof”, where the temperature and uniformity of heat can be much more extreme, is more difficult. The ceramic crystal structure called cordierite, which can be made from steatite, clay and alumina, also called steatite porcelain, is also used for cooking ware, as it has a low thermal expansion. Very low thermal expansion bodies such as those containing lithia or glass ceramics are also suitable for cooking ware, but glazing is difficult and food sticks to them so they are not popular. High-temperature-resistant ceramics are also used for modern cooker hobs.

For more decorative tableware or art ware, lower temperature porcelain, using more flux, may be used as it has good translucency at the cost of weaker mechanical strength. Typical vitreous art ware compositions are 20% ball clay and 30% kaolin together with 30% feldspar and 20% quartz. Conversely, in hotel ware, resistance to breakage is paramount and translucency is sacrificed (15% ball clay, 33% kaolin, 18% feldspar and 34% quartz).

Some interesting cooking wares have been devised in the past such as Wedgwood’s replacement for piecrusts in times when flour was in short supply.