14. Early Scientific Applications and the Role of Pottery Manufacturers

| 1842 Page: 366 of 418 Go To Page: | ◁◁ First | ◁ Previous | Next ▷ | Last ▷▷ |

Welwyn were also interested in a second technology from Germany which was the deposition of pyrolitic carbon onto ceramic rods to form resistors. Bull went to SECI where a small manufacturing facility for these carbon film resistors was being set up, and gathered sufficient information to set up manufacture in UK. With the encouragement of the Ministry of Aircraft Production Welwyn expanded. War broke out and the need for electronic equipment became more apparent, particularly high-powered resistors for radar. However, equipment also had to operate in the “steaming” jungle, the desert, at high altitude in planes, salt spray and freezing temperatures in Arctic convoys – the very conditions Welwyn components could endure. As the ceramic formers used by SECI and Welwyn were produced by Rosenthal, the outbreak of war made this source no longer available, so the Ministry of Aircraft Production introduced Welwyn to Royal Worcester, which had the capacity to meet Welwyn’s requirements as “domestic” demand for china had been curtailed during the war years. As stated earlier, a law was passed making it illegal to supply the home market with decorated pottery, so it was mainly produced to export to USA to earn foreign currency. Even undecorated white wares were produced sparingly and there were significant shortages during the war.

The Worcester factory was already being used as a shadow factory for the Steatite and Porcelain Products company, so on 23rd May 1941 they started production of insulators for aircraft radar and radio equipment. As stated earlier the majority of the wiring, glazing and firing of vitreous enamel resistors was transferred in early 1942 to the Royal Worcester factory, using ceramic tubes supplied by Steatite. A special kiln was built to process these. The facilities at Welwyn Garden City were kept in reserve in case the Worcester factory was damaged by enemy action.

At the end of the war Welwyn had grown to 800 people, but they were mainly in premises “borrowed” for the duration of the war. As the government was providing incentives to set up in ex-heavy industry areas, Bull moved Welwyn to Bedlington in Northumbria, partly because of his roots there. To finance this development Bull sold a minority interest in Welwyn to Royal Worcester, and they placed two members on the Welwyn Board, and he re-established his connections with SECI. Various new products were introduced in the following years including resistors for the Post Office, to be used in underwater repeaters for transatlantic cables. In 1952, Welwyn undertook its first basic scientific project and successfully identified ceramics with reduced alkali content to improve the performance of its carbon resistors. Later, Royal Worcester Industrial Ceramics co-operated significantly in this project. On the death of Bull in 1953 full control of Welwyn passed to Royal Worcester. At this time the pre-war links with Rosenthal were re-established. New products included capacitors made from vitreous enamel dielectric and copper foil electrodes, tin oxide resistors for computer applications and mains dropper resistors for TV sets.

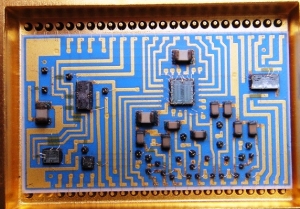

On 30th Sept 1954 Royal Worcester became a public company. Welwyn Electronics expanded more rapidly than the rest of the ceramics business eventually passing 50% of the turnover. Royal Worcester Ltd. was set up as a holding company in 1958 to cover all the electrical and industrial ceramics subsidiaries in the group, leaving Royal Worcester to look after the china. In 1960, development at Welwyn began on hybrid circuits, where a multiplicity of components was interconnected on a single ceramic substrate. They also instigated the development and manufacture of semiconductor chips.